Spas and wellness centers: drainage channels and point systems for optimal comfort

Wet, slippery, and dirty floors, bad odors, and stagnant water are all signs of a worn-out or inadequate drainage system.

Corrosion and wear-resistant, hygienic, and more: this is why stainless steel is the ideal choice for spas and wellness centers.

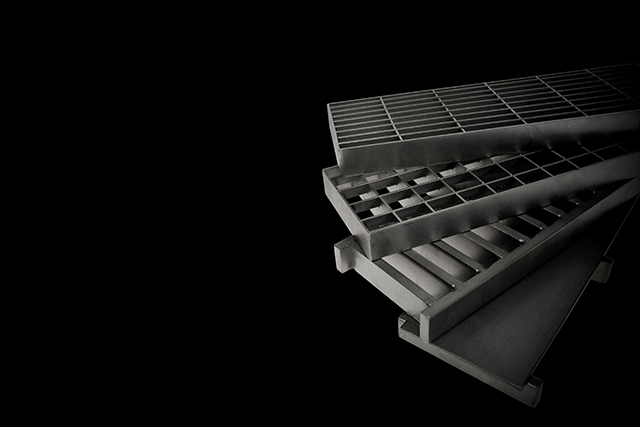

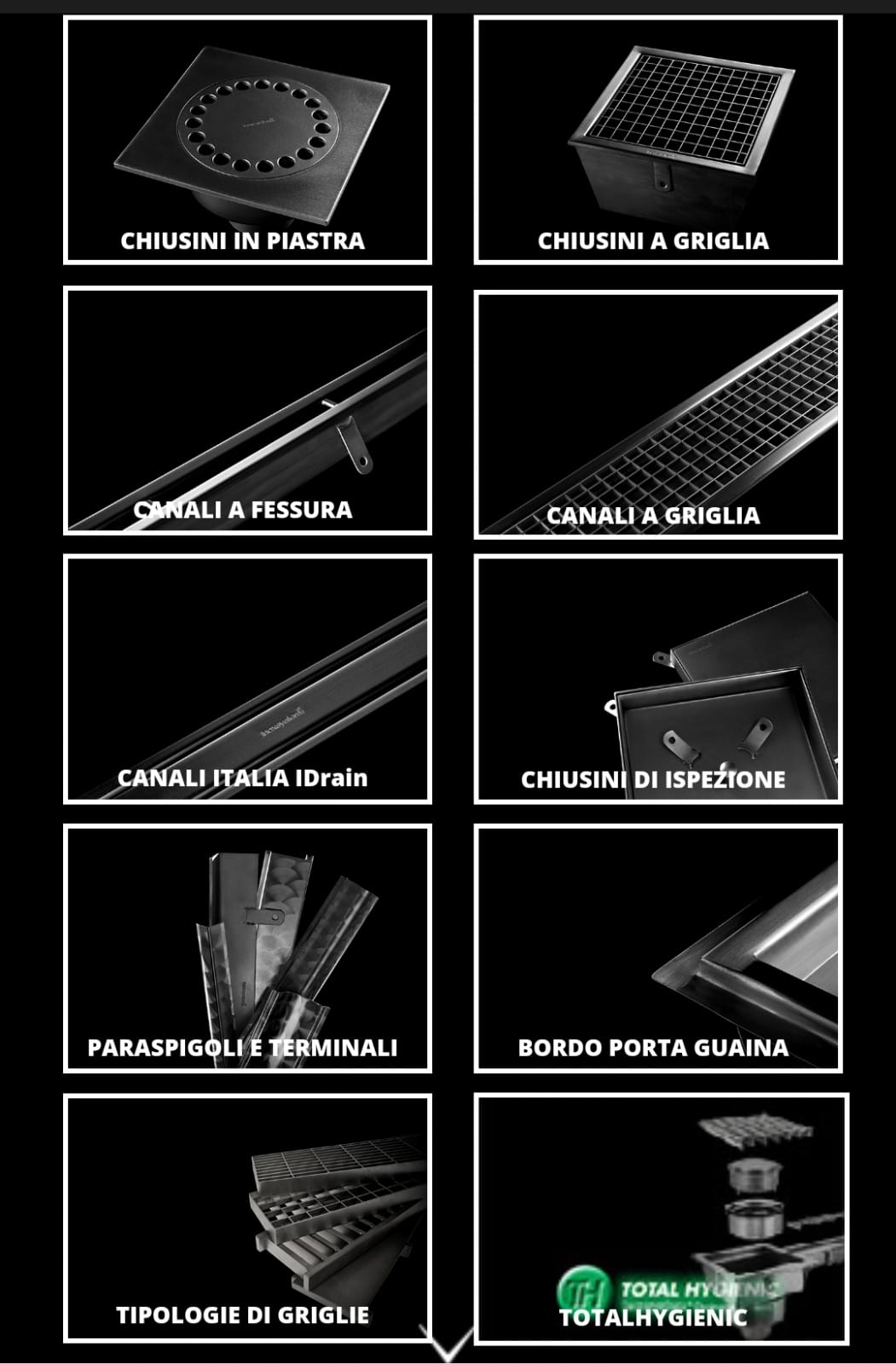

Each area requires a tailored drainage solution: from point systems like inspection-accessible drains in showers or slot channels like IDrain, to slotted or grated systems around pools, and drainage channels in walkways.

An effective drainage system should include an odor trap and, for outdoor pools, leaf-catching grates and baskets.

Beyond material selection, the care in design and installation makes the difference: this is how Inoxsystem® ensures it meets the unique needs of its customers.

A matter of well-being (and safety) Slippery or dirty floors, stagnant water, and unpleasant odors are all signs of poor or underperforming drainage systems. When this occurs in environments like pools, saunas, steam rooms, thermal areas, and wellness centers, solving the issue becomes crucial, as customer safety is at stake. These are particularly sensitive areas, where water or steam is present in large quantities. Water must be directed and drained quickly from surfaces to prevent pooling and the growth of germs and bacteria. In this context, well-designed drainage channels and expertly crafted floor drains play a key role. On one hand, they ensure effective water management, and on the other, they are designed to be walkable and seamlessly integrated into the aesthetic of spas and wellness centers. The value of stainless steel Replacing a worn-out water drainage system often requires extensive renovation work, which can easily become time-consuming. How can this be avoided? By choosing the right material from the start. Stainless steel, the undisputed star of Inoxsystem® products, offers numerous advantages, including:

Excellent resistance to corrosion and oxidation, ensuring greater durability over time;

high levels of hygiene, thanks to the chromium in its chemical composition, making it one of the most widely used materials in highly regulated environments like the food and pharmaceutical industries;

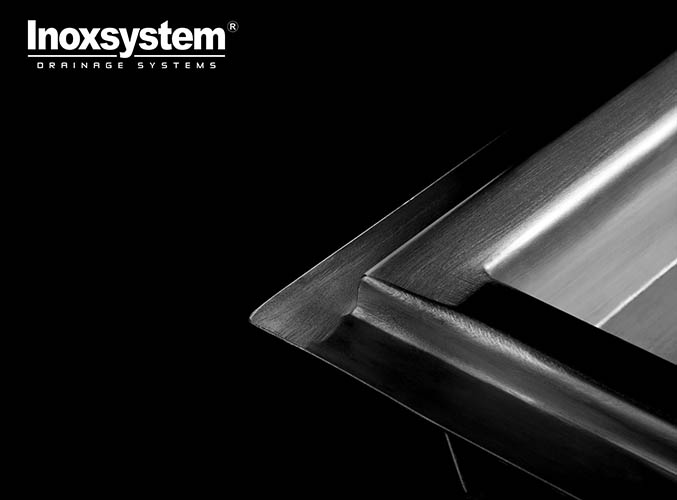

maximum watertightness, allowing drainage channels to be extended to any length without the risk of leaks.

Additionally, stainless steel is 100% recyclable, making it an environmentally sustainable option.

READ ALSO: His Majesty Stainless Steel and its irresistible advantages Spas and wellness centers: which drainage systems to choose Each wet area in a wellness center requires a tailored drainage system that meets its specific needs. Saunas, steam rooms, showers, as well as walkways and relaxation areas, may call for different types of components.

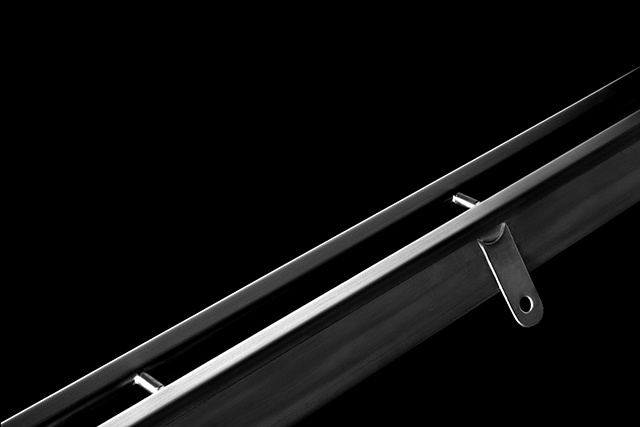

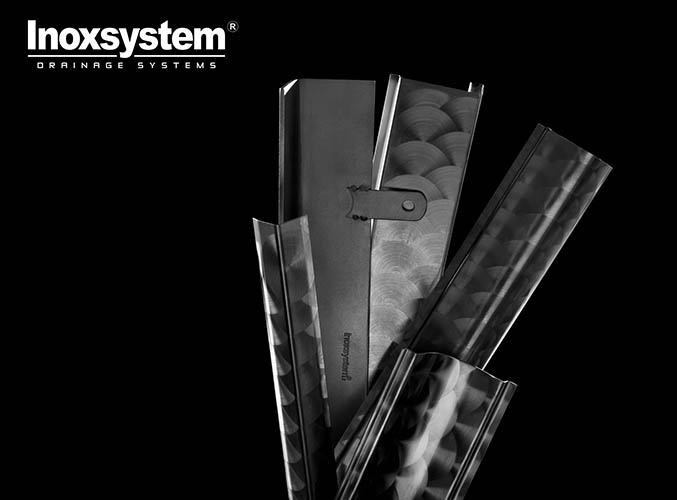

The most commonly installed systems in showers are point drains, typically featuring traditional inspection-accessible covers. However, there is also a growing demand for slot channels and inspection-accessible IDrain systems.

For walkways and specialized areas within the wellness center, linear systems are preferred to facilitate the creation of floor slopes.

The slope coefficient and self-slope are crucial within a high-performing drainage system, as they determine the rapid channeling of water and its complete drainage.

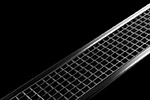

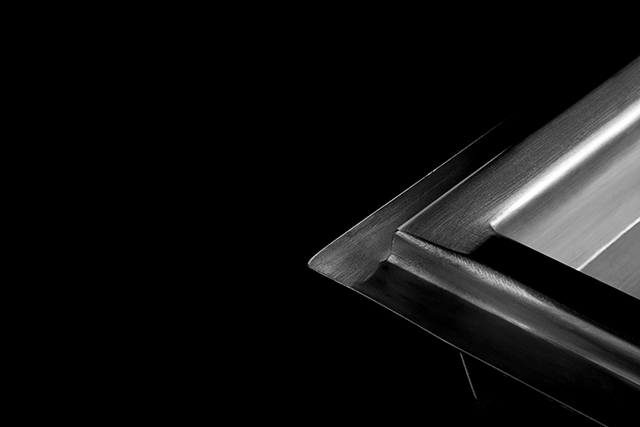

READ ALSO: Drainage systems: to each their own. Which one to choose? Cleanliness, safety and comfort around the pool When designing pools, the perimeter edge often calls for a slot drainage system that’s heel-proof or for a more designer option like IDrain channels. Another option is grated channels. The reason? They are fully accessible for inspection, have large capacity, and are safe for barefoot walking. To meet these unique needs, Inoxsystem® designs “multi-slot” grates with continuous 8mm heel-proof slots, made of folded stainless steel that can be tiled over. This product allows for safe foot traffic, quick pool maintenance, and a sleek, hidden design. Lastly, a high-quality drainage system must include an odor trap and, for outdoor pools, leaf-catching grates. These two elements are essential to keeping wellness areas clean and free from odors and debris. AISI 304 o AISI 316L: which is better? While the superiority of stainless steel over other materials is clear, another question often arises when discussing spas and wellness centers: should you opt for AISI 304 or AISI 316L? AISI 304 is an excellent choice, being durable, resistant, and antiseptic. However, AISI 316L is strongly recommended - and in some cases, mandatory - due to the high levels of chlorine and salts in wellness environments, which are highly corrosive. AISI 316L is more resistant to these elements, making it the better option depending on the type of water used in the facility. Custom solutions, guaranteed well-being As we’ve seen, the wellness industry features various environments that require drainage systems that are high-performing, safe, and long-lasting. Stainless steel helps achieve these goals. However, it's crucial that every drain cover or drainage channel is carefully crafted and strategically installed. Inoxsystem® produces custom drainage systems tailored to the specific needs of each client. While this phrase may seem overused, it perfectly captures the vision and flexibility that are essential for spas and wellness centers. Moreover, with a custom-designed flanging process that replaces plastic seals with silicone applied directly to the steel, the risk of leaks and water stagnation is significantly reduced. Discover our range of products Request more information Name Surname Email * Please fill in the required fields. Phone Company Subject Please fill in the required fields. U3BhcyBhbmQgd2VsbG5lc3MgY2VudGVycwo8cD48c3Ryb25nPkRhOjwvc3Ryb25nPnt7Zmlyc3QtbmFtZX19IHt7bGFzdC1uYW1lfX08L3A+CjxwPjxzdHJvbmc+RW1haWw6PC9zdHJvbmc+e3tlbWFpbH19PC9wPgo8cD48c3Ryb25nPk9nZ2V0dG86PC9zdHJvbmc+e3tzdWJqZWN0fX08L3A+CjxwPjxzdHJvbmc+QXppZW5kYTo8L3N0cm9uZz57e2F6aWVuZGF9fTwvcD4KPHA+PHN0cm9uZz5UZWxlZm9ubzo8L3N0cm9uZz57e3Bob25lfX08L3A+CjxwPjxzdHJvbmc+TWVzc2FnZ2lvOjwvc3Ryb25nPnt7bWVzc2FnZX19PC9wPg== I accept the Privacy Send Message More from the blog